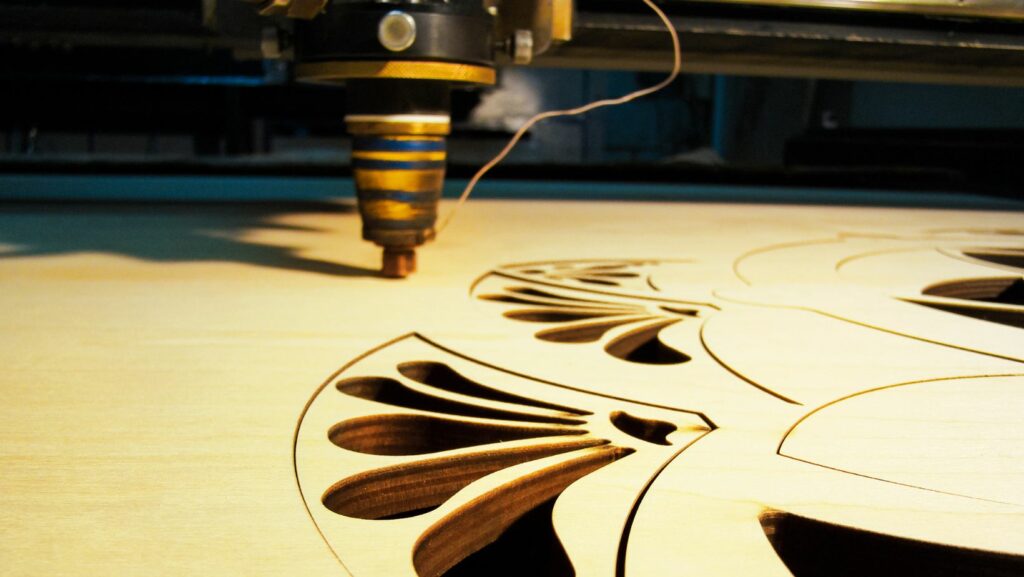

Crafting isn’t just a hobby—it’s a passion. And for those of us who love to create, there’s nothing like the precision and versatility of a wood laser cutting machine. From intricate designs to personalized gifts, the possibilities are endless.

But what exactly is a wood laser cutting machine? How does it work, and more importantly, how can it take your crafting game to the next level? I’ll delve into these questions and more, offering expert insights and tips along the way. Whether you’re a seasoned pro or just starting out, you’ll find something of value here. So let’s get started and explore the exciting world of wood laser cutting for crafts.

Wood Laser Cutting Machine for Crafts

Exploring the intricate domain of wood laser cutting for crafts unravels fascinating insights. As an experienced crafter or a fresh enthusiast, you may find your interests piqued as we delve deeper into the implications of this technology.

Exploring the intricate domain of wood laser cutting for crafts unravels fascinating insights. As an experienced crafter or a fresh enthusiast, you may find your interests piqued as we delve deeper into the implications of this technology.

Key Features to Consider

When considering a wood laser cutting machine for crafts, main features come together narrating a tale of functionality, precision, and customization.

- Power Output: Denotes the ability of the laser to cut through different materials. A power output of 40W, for instance, can cleanly slice through 1/4″ of soft wood.

- Engraving Capability: Tailors the machine to detail-oriented tasks, for instance, inscribing patterns on a wooden plaque.

- Ease of Use: Includes features like touch screen controls, software compatibility, and quick setup procedures.

- Safety Features: There’s no skimping on protective measures—from enclosed designs preventing accidental exposure to lasers, to built-in exhaust fans countering harmful fumes.

- Versatility: Marks ability to cut wide range of thicknesses and types of woods, broadening the possibilities of your crafting.

Types of Machines Available

In the market of wood laser cutting machine for crafts, various models cater to distinct needs, presenting a myriad of choices:

In the market of wood laser cutting machine for crafts, various models cater to distinct needs, presenting a myriad of choices:

- CO2 Laser Cutters: Emit a powerful laser suitable for a variety of materials like wood or acrylic. For example, EPILOG Zing 16 sports a 40W CO2 Laser for high utility crafting.

- Fiber Laser Cutters: Suiting industrial use, these may lack precision for crafting.

- Diode Laser Cutters: Offering lower power, these machines are perfect for intricate designs. An example being the compact Ortur Laser Master 2 with its detailed engraving capabilities.

Delving into each option’s intricacies lets crafters paint their designs on the canvas of wood with laser precision. It’s easy to see how these machines translate artistic visions into tangible wooden masterpieces.

Benefits of Using a Laser Cutter for Woodworking

Delving deeper, let’s explore the distinct advantages of employing a wood laser cutting machine for crafts in the realm of crafting. Advantages such as unparalleled precision and warp-speed efficiency provide these machines a distinct edge.

Precision and Detail

Harnessing a laser cutter, I can achieve intricate patterns and designs on a wooden surface. The laser’s fine point concentrates an intense burst of energy on a minuscule area, carving out delicate and detailed designs. This precision lends itself well to projects that require a high degree of detail, like intricate scrollwork.

Speed and Efficiency

When I talk about speed and efficiency, laser cutters outshine most other woodworking tools. They harness the power of computer-programming, speeding through repetitive tasks with dynamic swiftness, making them a perfect choice to handle large batches of identical pieces. Suppose a craftsman needs to produce 50 identical table coasters.

Essential Safety Tips for Operating a Laser Cutter

Let’s now focus on the significant aspect of using a wood laser cutting machine for crafts – safety. We’ll explore key safety protocols for operating the machines, which include the use of personal protective equipment and specific workspace safety measures.

Let’s now focus on the significant aspect of using a wood laser cutting machine for crafts – safety. We’ll explore key safety protocols for operating the machines, which include the use of personal protective equipment and specific workspace safety measures.

Personal Protective Equipment (PPE) plays a paramount role in safeguarding operators from potential hazards posed by laser cutters. For eye protection, laser safety goggles are a must. They shield the eyes from the intense light emitted during the cutting process. Similarly, fire-resistant gloves offer hand protection, especially when handling cut pieces that may still be hot. Also, operators should wear a lab coat or another form of fire-resistant clothing.